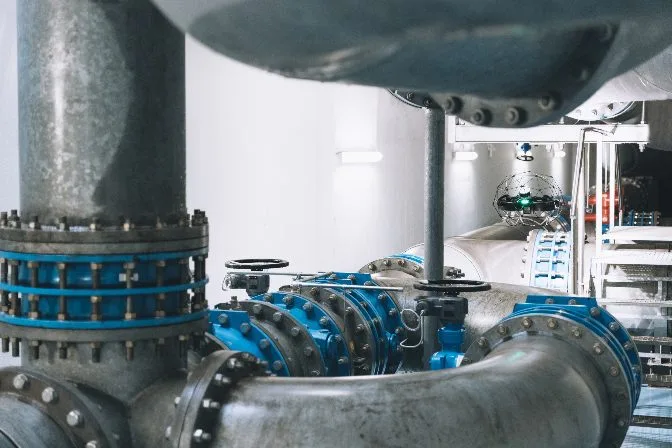

Visual inspection is one of the most fundamental and widely used methods in asset maintenance and safety checks. It involves examining an object or structure with the naked eye, without the need for complex tools or equipment. However, this doesn’t mean it’s simple. A skilled inspector must have a deep understanding of what to look for, as even small anomalies can indicate major issues that could lead to failure or accidents if ignored. Traditionally, visual inspections were conducted manually, with inspectors walking around or entering assets like boilers, pipelines, and storage tanks. While this method is still used, advancements in technology have introduced Remote Visual Inspection (RVI), which allows for safer and more efficient data collection from a distance. With RVI, inspectors can use drones, robotic crawlers, or cameras to gather high-quality images and videos of hard-to-reach areas. This not only improves safety but also reduces costs and downtime associated with traditional methods. [Visual inspection NDT—also called visual testing—is just one of the non-destructive testing (NDT) methods that inspectors use. Learn more about NDT in this in-depth guide.] This guide will walk you through the basics of visual inspections, their importance, the industries that rely on them, other inspection techniques, and how modern tools like drones are transforming the field.  What Is the Purpose of a Visual Inspection? Visual inspections are among the oldest and most effective ways to assess the condition of an asset during routine maintenance. The main objective is to identify any potential issues that may require attention before they escalate into serious problems. For instance, when inspecting a boiler, an inspector might look for signs of: Cracks or deformations in welds Corrosion on internal surfaces Leakage or structural damage Malfunctioning components or support systems By catching these issues early, inspectors help prevent costly repairs, downtime, and, most importantly, safety hazards. In critical environments such as power plants or chemical facilities, visual inspections are often carried out by certified professionals following strict industry standards. Visual inspections are a vital part of maintenance across nearly every industrial sector. From oil rigs to food processing plants, visual inspections are the first step in identifying potential problems. Here are some key industries that depend on this technique: Oil & Gas Power Generation Chemical Manufacturing Mineral Mining Maritime & Shipping Food & Beverage In each of these sectors, regular visual checks help ensure the integrity and safety of large, complex assets. While visual inspections are the most common, they are just one of many non-destructive testing (NDT) methods used in industry. NDT encompasses a variety of techniques that allow inspectors to evaluate the condition of materials and structures without causing damage. Some of the most widely used include: 1. Ultrasonic Testing (UT) – Uses sound waves to detect internal flaws. 2. Radiography Testing (RT) – Utilizes X-rays or gamma rays to reveal hidden defects. 3. Magnetic Particle Testing (MT) – Identifies surface and near-surface discontinuities using magnetic fields. 4. Acoustic Emission Testing (AE) – Detects emissions caused by material stress or cracking. 5. Liquid Penetrant Testing (PT) – Applies a dye to find surface-breaking flaws. 6. Leak Testing (LT) – Looks for leaks in pressure vessels or piping systems. Each method has its own advantages and is chosen based on the type of asset, environment, and specific concerns. As we’ve seen, visual inspections don’t always require an inspector to be on-site. With the rise of advanced imaging and robotics, Remote Visual Inspection (RVI) has become a game-changer. RVI tools, such as drones and robotic crawlers, allow inspectors to collect high-resolution images and video from locations that are otherwise inaccessible or unsafe. For example, in mining operations, after a blast, it's too dangerous for humans to enter the area immediately. But a drone can fly in, capture footage, and help determine whether it's safe for workers to proceed. Similarly, inspecting large oil tanks or wind turbines can be risky due to height and exposure to elements. Drones eliminate the risk of falls and provide clear, detailed visuals for analysis. Here’s how an inspector might use RVI: Send a drone into a boiler to capture all necessary visual data Review the footage to spot any irregularities or damage Though the data is viewed on a screen, the process remains a visual inspection—just done remotely and more efficiently. Even in residential and commercial building inspections, RVI is becoming more common. Using video call platforms like Zoom or FaceTime, inspectors can conduct virtual walkthroughs from anywhere in the world. Drones are not the only tool for RVI, but they are rapidly becoming the preferred choice for many inspectors. They offer mobility, precision, and ease of access to areas that would otherwise be difficult or dangerous to reach. For example, Flyability’s Elios 3 is designed specifically for confined spaces, featuring oblique lighting that helps inspectors see depth and detail clearly. Using drones for visual inspections brings several benefits: Safety: Eliminates the need for inspectors to enter hazardous environments. Cost Efficiency: Reduces the need for scaffolding, time, and labor. Data Quality: Provides high-resolution images and video that can be stored and reviewed later. As technology continues to evolve, the role of drones in visual inspections will only grow, making the process faster, safer, and more accurate than ever before.  Luohe Letone Hydraulic Technology Co., Ltd , https://www.litonghose.comA Comprehensive Guide to Visual Inspections

Which Industries Rely on Visual Inspections?

Other Common Inspection Techniques

Remote Visual Inspection (RVI)

The Elios 3 flying inside a salt mine

The Elios 3 flying inside a salt mine

Drone footage of a damaged wind turbine that was struck by lightning

Drone footage of a damaged wind turbine that was struck by lightningHow Drones Enhance Visual Inspections