A visual inspection is a method used to examine an asset using only the naked eye. It is one of the most fundamental and widely used techniques in maintenance and safety assessments across various industries. While no special equipment is always required, this type of inspection demands proper training so that the inspector can identify potential issues effectively. The ability to recognize subtle signs of wear, damage, or deterioration is crucial for ensuring the integrity and safety of the inspected asset. Traditionally, visual inspections have been conducted by walking around or entering an asset, such as a boiler, to inspect every visible part. However, with the development of Remote Visual Inspection (RVI) tools, inspectors can now collect data without being physically present, significantly changing how these inspections are carried out. Some RVI technologies are so advanced that they allow inspectors to rely almost entirely on the visual data collected for their evaluations. This not only improves efficiency but also enhances safety in hazardous environments. [Visual inspection NDT—also called visual testing—is just one of the non-destructive testing (NDT) methods that inspectors use. Learn more about NDT in this in-depth guide.] This guide provides comprehensive information on visual inspections, including their purpose, the industries that rely on them, other inspection techniques, and how drones can enhance the process. Whether you're a professional in the field or simply curious about industrial maintenance, this guide will help you understand the importance and application of visual inspections.  What Is the Goal of a Visual Inspection? Visual inspections are among the oldest and most trusted methods for assessing the condition of an asset during routine maintenance. Their primary objective is to detect any anomalies or issues that may require repair or further investigation. For example, when inspecting an industrial boiler, an inspector might look for cracks in welds, corrosion on the walls, leaks, or problems with supporting components. Identifying these issues early helps prevent costly repairs and potential accidents. In critical infrastructure like boilers or pressure vessels, even a small oversight could lead to serious consequences. That’s why such inspections are usually performed by licensed professionals who follow strict protocols to ensure accuracy and safety. Visual inspections are widely used across all industrial sectors. The reason is simple: examining an asset with the naked eye is one of the most effective and straightforward ways to detect flaws. Here are some key industries that incorporate visual inspections into their regular maintenance routines: Any industry that uses large, complex assets typically starts with a visual inspection as the first step in its maintenance process. Although visual inspection is the most common technique, it is just one of many types of inspections used in non-destructive testing (NDT). NDT refers to a range of methods that allow inspectors to assess the condition of an asset without causing any damage. Here are some other common inspection techniques: 1. ULTRASONIC TESTING (UT) – Uses high-frequency sound waves to detect changes in material properties. 2. RADIOGRAPHY TESTING (RT) – Involves using X-rays or gamma rays to find internal defects. 3. MAGNETIC PARTICLE TESTING (MT) – Detects surface and near-surface flaws by analyzing magnetic field disruptions. 4. ACOUSTIC EMISSION TESTING (AE) – Identifies defects by monitoring acoustic signals generated by stress or damage. 5. LIQUID PENETRANT TESTING (PT) – Applies a liquid to detect surface-breaking flaws by observing its penetration. 6. LEAK TESTING (LT) – Examines structures for leaks to identify potential weaknesses. As mentioned earlier, visual inspections don’t always need to be done in person. With advancements in camera and robotics technology, remote visual inspection (RVI) has become increasingly popular. Inspectors often prefer RVI when the area to be inspected is dangerous or difficult to access. For instance, after a mine blast, entering the site is too risky, but a drone can safely gather visual data from the air. Another example is inspecting large oil storage tanks. Climbing scaffolding at great heights is dangerous, but a drone can safely capture high-quality images and video without risking human safety. Here’s how RVI fits into an inspector’s workflow: Even though the inspection is done remotely, the process remains fundamentally the same—just conducted through digital data instead of direct observation. Home and building inspections are also benefiting from RVI. Using video calling platforms like Zoom or FaceTime, an inspector can conduct a virtual walkthrough from anywhere, making the process more efficient and accessible. Drones are not the only tool for RVI, but they are becoming the preferred choice due to their flexibility, control, and image quality. While other methods like rope-based cameras or robotic crawlers exist, drones offer a faster and safer alternative. Drones like Flyability’s Elios 3 come equipped with features such as oblique lighting, which allows inspectors to better visualize surfaces and detect flaws without being physically present. Here are some key benefits of using drones for visual inspections: With continuous improvements in drone technology, the future of visual inspections looks more efficient, safer, and more accurate than ever before.  Big size (up to 12"), ultra-abrasion, high/low temperature and corrosion resistant, and multiple length choices, Letone industrial hose are ideal for industries like construction, chemical, bulk material delivery, steel mills, oil & gas, machinery and equipment manufacturing, high pressure cleaning, F&B and applications of extremely working environment. Industrial Hose,Pumping Hose,Oilfield Hose,Concrete Hose Luohe Letone Hydraulic Technology Co., Ltd , https://www.litonghose.comVisual Inspections: A Complete Guide

Which Industries Use Visual Inspections?

Other Kinds of Inspections

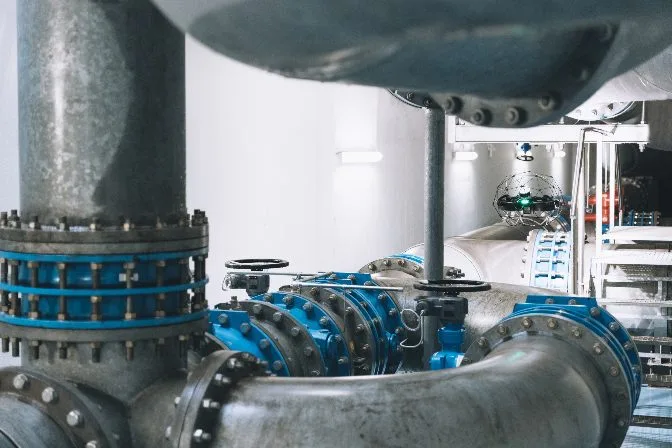

Remote Visual Inspection (RVI)

The Elios 3 flying inside a salt mine

The Elios 3 flying inside a salt mine

Drone footage of a damaged wind turbine that was struck by lightning

Drone footage of a damaged wind turbine that was struck by lightningHow Drones Can Help with Visual Inspections