sulfate-free,sulfuric acid,sulphate,sulfuric acid MIANYANG KEJIXIN TRADING CO., LTD , https://www.kjxnitrate.com

In the modern industrial landscape, smart instruments are rapidly gaining traction across various sectors, particularly within the process industry. These innovative tools bring numerous advantages that make them indispensable for improving operational efficiency and decision-making. Among these, smart transmitters stand out as a key component, offering unique functionalities that cater to specific needs in the industry. They help process managers maximize their investments by providing precise data and insights. Despite their benefits, however, smart instruments have introduced new challenges to traditional calibration practices. If you're curious about what smart transmitters are, how they work, and the best methods for calibrating them, keep reading to uncover the answers.

### What Exactly Is a Smart Transmitter?

A transmitter is a fundamental tool in the process industry, designed to measure critical variables like temperature, pressure, and flow. Its primary function is to produce an output signal proportional to the measured values, enabling operators to manage their processes more effectively.

Smart transmitters take this concept further by incorporating advanced microprocessors. These processors enhance the device's capabilities, offering superior diagnostics, stability, and accuracy—thanks in part to digital compensation techniques that address nonlinear readings. Additionally, many smart transmitters connect seamlessly with other measurement devices, creating integrated systems that streamline operations.

HART (Highway Addressable Remote Transducer), FOUNDATION Fieldbus, Wireless HART, and Profibus are among the widely adopted communication protocols supported by smart transmitters. Of these, HART remains the most prevalent today.

### Calibration vs. Configuration: Understanding the Difference

One common source of confusion lies in the distinction between calibration and configuration. While there’s no universally accepted definition for either term, they refer to distinct processes.

Configuration involves adjusting the transmitter’s settings to align with specific process requirements, such as altering its transmission and measurement capabilities. On the other hand, calibration is a separate but equally important procedure. It entails comparing the transmitter against a traceable reference point to identify any deviations or drifts. While minor adjustments might occur during calibration, significant changes are not typically required unless necessary.

### Why Is Regular Calibration Essential for Smart Transmitters?

Even though smart transmitters boast digital outputs, regular calibration is crucial to maintain optimal performance. Here are some compelling reasons why calibration should never be overlooked:

- **Environmental Factors:** Smart transmitters often operate in demanding environments where exposure to extreme temperatures, humidity, or vibrations can cause drift over time.

- **Regulatory Compliance:** The process industry must adhere to stringent regulations concerning safety, quality, and environmental standards. Proper calibration ensures compliance with these requirements.

- **Economic Benefits:** Accurate measurements lead to sound decision-making, reducing costs associated with inefficiencies or errors.

- **Workplace Safety:** Consistent calibration contributes to safer working conditions by minimizing risks linked to faulty equipment.

- **Product Quality:** By maintaining accurate readings, calibration supports consistent product quality through optimized processes.

### How Do You Calibrate a Smart Transmitter?

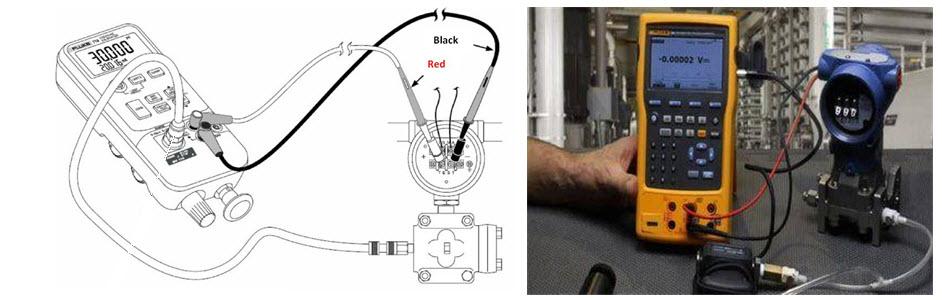

The calibration process for smart transmitters is often referred to as "digital trimming." This method involves two primary approaches:

1. **Current Loop Trim:** This step focuses on fine-tuning the output of the Digital-to-Analog converter.

2. **Sensor Trim:** During this phase, the transmitter’s variable readings are aligned with inputs from a highly accurate reference device.

In both cases, the transmitter receives stimuli at both low-range (LRV) and high-range (URV) values. These stimuli represent typical process variables encountered during operation. The resulting outputs are then recorded using handheld communicators. Any discrepancies between the input and output signals are analyzed, and necessary corrections are applied. Trimming should occur whenever significant drifts are detected in either the sensor or the converter circuitry beyond acceptable thresholds.

If you’re unfamiliar with these procedures, it’s advisable to consult professionals who specialize in transmitter services. Companies like The Transmitter Shop offer comprehensive calibration solutions tailored to meet your needs.

By understanding the importance of calibration and staying proactive in maintaining your smart transmitters, you can ensure reliable performance, enhanced productivity, and long-term cost savings.