"Mining tools" is a general term that refers to all the equipment and machines used in the process of extracting minerals from the earth. These tools are essential for accessing valuable resources such as metals, coal, and precious stones, which are integral to everyday life—from the electronics we use to the cars we drive. Before diving into specific tools, it's important to understand the various mining methods that dictate the types of equipment used. This guide will first explore the main mining techniques, then break down the tools associated with each. By understanding these methods, you'll gain a clearer picture of how mining tools are tailored to meet the unique challenges of each extraction process. Mining can be broadly categorized into four main types: underground, open-pit (surface), placer, and in-situ mining. Each method is chosen based on the type of mineral being extracted and its location beneath the surface. The basic process of mining involves three key steps: extraction, material handling, and processing. These steps are adapted depending on whether the operation is above or below ground. Surface mining is used when the target minerals are close to the Earth’s surface. Common techniques include strip mining, open-pit mining, quarrying, in-situ leaching, and placer mining. When minerals are too deep for surface mining, underground techniques are employed. These methods require careful planning due to the confined and hazardous nature of the environment. Soft rock mining typically does not require explosives, while hard rock mining does. This distinction affects the choice of tools and equipment used in each environment. Soft Rock Mines include salt, coal, bauxite, and potash, which can be extracted using specialized machinery. Hard Rock Mines, such as those for copper, gold, and uranium, rely on hydraulic drills and explosives to access deeper deposits. There are many types of mining tools, each suited to a specific mining method and environment. This guide organizes these tools by category, helping you understand their roles and functions. Here’s a general list of mining tools and equipment: Personal protective equipment (PPE) is crucial for miner safety. Essential items include: Surface mining requires heavy machinery such as: Underground mining tools include: These tools are designed to operate in enclosed, low-light environments and are often electric or battery-powered to reduce emissions. Additional tools used in both surface and underground mining include hoppers, chutes, conveyor belts, crushers, and mills. These tools help transport, process, and store extracted minerals efficiently. Mining Tools: rugged and ready for hard work The mining industry has evolved significantly over time, but the need for durable and reliable equipment remains unchanged. With the rise of digital technologies, drones and LiDAR scans are now playing a major role in mine mapping, safety, and efficiency. Underground drones like the Elios 3 are revolutionizing inspections, allowing teams to safely access areas previously deemed too dangerous. As technology continues to advance, the future of mining looks more efficient, safer, and more sustainable than ever before.

Customizable High Quality Aluminium Tube Coiled,Source factory stock,Customizable High Quality Aluminium Tube Coiled,High Quality Aluminium Tube For Heat Exchanger,High quality Aluminium Tube Coiled

Our company has always had strict quality control standards in the market of refrigeration and heat exchange equipment, focusing on providing customised services to our customers. Not only do we have high requirements for the selection of raw materials, but we also keep up to date with the latest production processes and have high testing standards.

Our company mainly produces products for:Fin Evaporator.Fin Type Condenser.Capillary Tube. Coolant Reservoir.Plate Reinforcement Parts.Stamped Parts.Aluminum Tube.Instrument Testing Equipment.

Aluminum Tube,Rectangular Aluminum Tube,Aluminium Tube Coiled,Customizable Rectangular Aluminum Tube Xinxiang Yukun Refrigeration Technology Co.Ltd , https://www.yukunevaporator.comMining Tools — A Guide to Mining Equipment and Mining Machines

Types of Mining Methods

Surface Mining Methods

Open-pit mine | Source: Adam Rhodes on Unsplash

Open-pit mine | Source: Adam Rhodes on UnsplashUnderground Mining Methods

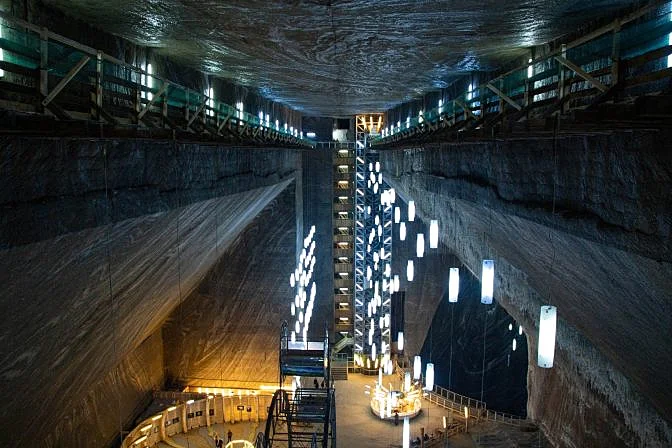

Salt mine | Source: Szabolcs Molnar from Pixabay

Salt mine | Source: Szabolcs Molnar from PixabayMining Equipment for Soft Rock Mines Vs. Hard Rock Mines

Mining Tools and Equipment

Mining PPE

Surface Mining Equipment

Blasthole drill | Source: Cat Models

Blasthole drill | Source: Cat ModelsUnderground Mining Equipment

Elios 3 drone | Source: Flyability

Elios 3 drone | Source: FlyabilityOther Mining Tools

If you have any interest, please feel free to contact us. We can provide customized service according to your drawings or samples.