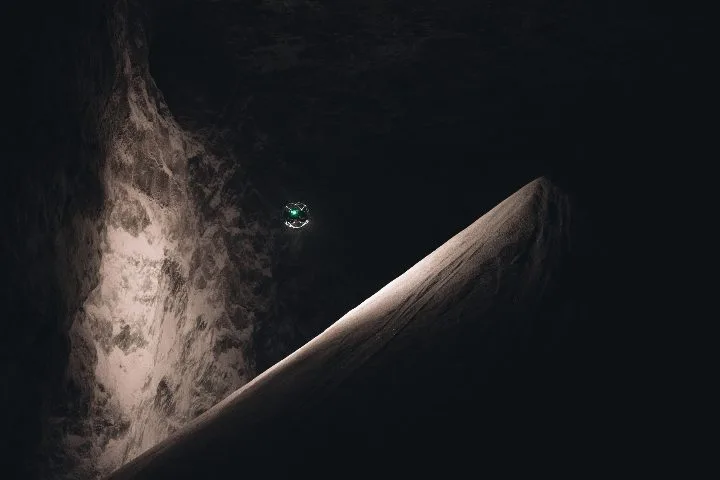

At a salt mine in Germany, the Elios 3 drone equipped with LiDAR technology has revolutionized the way stockpile measurements are taken, significantly improving both safety and accuracy for mining engineers. Speed Traditional manual methods of calculating salt stockpile volumes are slow and labor-intensive. The Elios 3 allows surveyors to stay on the ground, flying the drone through the area to quickly generate precise 3D models of the stored material. Accuracy The 3D models created by the Elios 3 offer a level of precision that manual calculations simply can’t match. This ensures more reliable data for inventory and planning purposes. Safety Climbing large salt piles is dangerous and risky. With the Elios 3, surveyors no longer need to physically climb these structures, reducing the risk of accidents and improving overall safety during data collection. Volume calculations play a crucial role in mining and aggregate operations, where large quantities of materials are stored over time. These calculations help determine how much material is available, how much is being used, and what is needed for backfilling or future extraction. Traditionally, this process has been done manually. Surveyors climb stockpiles to take measurements, use handheld sensors, or rely on truck weights to estimate volume changes. However, these methods are not only slow but also prone to inaccuracies, which can lead to poor decision-making and inefficiencies. Despite these challenges, volume tracking remains essential. Mines spend significant time and resources on these calculations, even though the results are often unreliable. This is why the adoption of new technologies like the Elios 3 is so important. In a German salt mine, the surveying team is responsible for mapping the entire facility and maintaining an accurate inventory of the salt stored within it. Monthly surveys are conducted to track stockpile volumes, requiring one full day of work for data collection and another day for analysis. Surveyors climb the salt cones to measure their height from the top to the ceiling. They then use CAD software to draw the shapes and calculate the volumes. This method is not only physically demanding but also inefficient and less accurate than modern alternatives. Engineers at the mine learned about the Elios 3, a LiDAR-equipped indoor drone developed by Flyability. It uses FlyAware SLAM technology to create real-time 3D maps as it flies, making it ideal for challenging environments like underground mines. Given the drone’s proven performance in similar applications, the mine decided to test it for stockpile measurements. Their goal was to improve speed, accuracy, and safety by eliminating the need for manual climbs and outdated measurement techniques. The team hoped that using the Elios 3 would not only provide better data but also make the process safer and faster for their staff. The test was a clear success. The Elios 3 allowed the surveyors to create high-quality 3D maps of multiple salt stockpiles efficiently and accurately. Here are some key outcomes: "I had never flown a drone before, but the application is really user-friendly. It's stable, easy to handle, and the interface is great," said one mining engineer. Both engineers and surveyors were highly satisfied with the performance of the Elios 3. The mine is now considering adopting the drone for all its volume calculations, which would save time, improve data quality, and enhance safety across the operation. Using the Elios 3, the team can also explore areas that may be unstable or difficult to access, without putting personnel at risk. Beyond stockpile measurements, the drone has the potential to transform how the mine is mapped and managed. The head of the surveying department is interested in using the Elios 3 to create detailed 3D maps of the entire mine, replacing current 2D plans with more accurate and comprehensive representations. This innovation marks a major step forward in how mining operations can leverage technology to improve efficiency, safety, and decision-making in the field.

Calibrator, sizing unit, calibrating sleeve for Pipe Size

Calibrator: made of Brass

Internal pipe cooling system design

(Air exhausts system for cooling inside pipe from Die head) Adaptor with pressure sensor

Bush:1pc for each diameter

Pin:2pcs for each diameter

Calibration sleeve:3pcs for each diameter

Calibrating Unit,Calibrating Sleeve,Changeable Calibrator,Laminated Sizing Sleeve KonRun Intelligent Machinery(Ningbo) Co., Ltd. , https://www.konrunmachine.comElios 3 Enhances Safety and Precision in Salt Mine Stockpile Measurements

Key Advantages at a Glance

Introduction

Customer Needs

Solution

Results

Conclusion