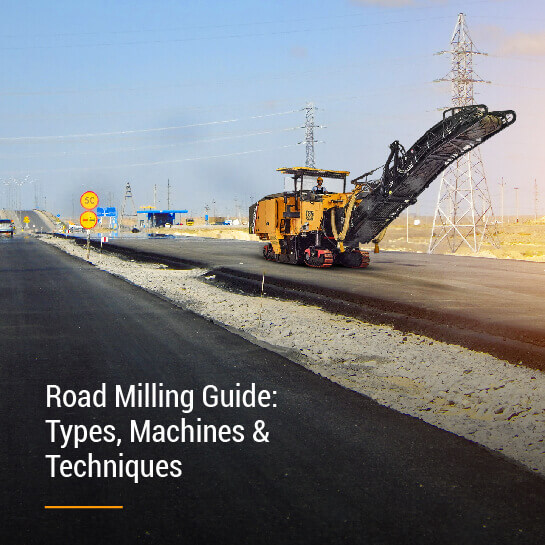

Building and maintaining roads is a complex process that demands precision at every stage to ensure the long-term durability and safety of the infrastructure. One of the most crucial steps in road rehabilitation is milling—a technique used to remove the top layer of existing pavement. This operation is carried out by specialized machines designed to prepare the surface for new asphalt layers. In this article, we explore everything you need to know about road milling, from its purpose and benefits to how it's done and how to choose the right equipment for your project. What is Road Milling? Road milling, also known as cold planing, is a key process in road construction where the top layer of an existing asphalt surface is removed. This method is essential for preparing the roadbed for resurfacing, ensuring that the new material doesn’t raise the elevation of the road. By eliminating worn, damaged, or deteriorated asphalt, milling creates a smooth and even base that allows new layers of asphalt to bond properly. It’s not just about resurfacing—it’s about restoring the original structure and integrity of the roadway, making it safer and more durable over time. Milling offers numerous advantages that make it a go-to solution in modern road maintenance and construction. Here are some of the main benefits: The milling process involves using heavy-duty road milling machines equipped with a rotating drum fitted with cutting teeth. These machines grind and remove the top layer of asphalt to the desired depth. Operators control the machine’s speed and drum rotation to achieve uniform surface removal. Depending on the project, these machines can mill different widths and depths, making them highly adaptable for various road conditions and requirements. Selecting the appropriate road milling machine is vital for the success of any road project. Here are key factors to consider: SANY India is a leading name in the construction machinery industry, known for its innovation, quality, and reliability. Our range of road milling machines is specifically designed to meet the demanding needs of modern road construction. Here are some of our top models: Investing in the right road milling machine can greatly enhance the efficiency, accuracy, and cost-effectiveness of your road construction projects. Whether you're upgrading an existing road or building a new one, choosing the right equipment is crucial. SANY India’s milling machines, such as the SCM1000C-8, SCM1300C-8, and SCM2000-8S, are engineered to deliver exceptional performance and reliability. Explore our range today and take your road projects to the next level.

Vacuum forming display rack is one of the props. It has a unique appearance, powerful functions, and also has advertising effects to achieve better profitability.

Vacuum forming display is the image of a customer's product and sometimes the only point of sale or promotional product that comes into contact with the customer. Therefore, your vacuum forming display must be outstanding,eye-catching, and durable.

Yiyongli can design and produce any type of vacuum formed display rack, using vacuum forming technology combined with spraying, screen printing, and stickers to achieve unique effects. The materials used are mostly ABS and acrylic, and can be customized for exhibition racks, clothing display racks, food display racks, lubricating oil display racks, toy display racks, digital product display racks, daily necessities display racks, information display racks, jewelry display racks, promotional display racks and cosmetics display racks, etc.

Vacuum Forming Display Rack,Vacuum Forming Display Stand,Vacuum Forming Plastic Display,Vacuum Forming Comestic Display,Vacuum Forming Display Dongguan Yiyongli Industrial Co.,Ltd. , https://www.absthermoforming.com

Benefits of Road Milling

How Does Road Milling Work?

Choosing the Right Road Milling Machine

Top Road Milling Machines from SANY India

In Summary