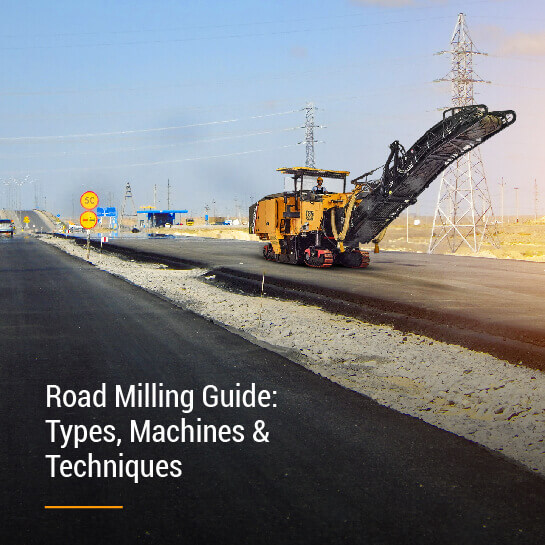

Building and maintaining roads is a complex process that demands precision at every stage to ensure long-lasting and safe infrastructure. One of the most important steps in this process is milling, a technique used to remove the top layer of an existing pavement. This is typically done using specialized machines designed for efficient surface preparation before new asphalt is laid. In this article, we’ll explore everything you need to know about road milling—its benefits, how it’s performed, and how to choose the best machine for your project. What is Road Milling? Road milling, also known as cold planing, is a crucial step in road construction where the top layer of asphalt is removed. This process helps prepare the surface for new layers of material, ensuring that the overall height of the pavement remains consistent. By eliminating worn or damaged asphalt, milling creates a smooth and even base for new materials to adhere to. It not only improves the quality of resurfacing but also preserves the original design and structure of the road, making it an essential part of any road maintenance or upgrade project. Milling offers numerous advantages that make it a popular choice in road construction and maintenance. Here are some key benefits: The milling process involves the use of large, specialized road milling machines equipped with rotating drums that grind and remove the pavement layer. These machines can adjust their depth and width based on the specific needs of the project. Operators control the speed and drum rotation to ensure a uniform and even surface removal, optimizing both performance and results. SANY India is a leading name in the construction machinery industry, known for its innovation, reliability, and high-quality products. Our range of road milling machines is specifically designed to meet the demands of modern road construction projects. Each model is engineered to deliver exceptional performance, durability, and efficiency, ensuring optimal results for every job. Choosing the right road milling machine plays a vital role in the success of your road construction and maintenance projects. Understanding the milling process and selecting equipment with the right features ensures efficiency, accuracy, and cost-effectiveness. If you're looking for reliable and high-performing machines, consider the SANY India models like the SCM1000C-8, SCM1300C-8, and SCM2000-8S. These machines are built to deliver outstanding performance and help you achieve better results on your next project.

Yiyongli is a leading supplier of custom plastic large part by vacuum forming process across a variety of industries.We can provide product design and manufacturing engineering assistance and is ISO 9001:2015 registered.

Vacuum forming is a very economical method for producing large plastic parts.It offers lower cost tooling and quicker prototyping than other technology. Vacuum forming is best choice compared to other manufacturing methods such as complex fabricated sheet metal or fiberglass, in large, complex shapes which require a lot of metal fabrication, grinding and finishing. Vacuum forming also compares favorably to injection mould in big plastic parts when small quantities.

Vacuum forming large parts are single component parts that come out of the actual product or a substantial part of the finished product. Usually they are enclosures or housings for equipment.Applications of vacuum forming large parts are seen in many industries, including medical equipment panels ,machine enclosures, engine covers for aerospace, transportation or construction industries, and rail-car interior trim or seat components.

Vacuum Forming Large Parts,Vacuum Forming Plastic Products,Vacuum Forming Plastic Parts,Thermforming Large Parts,Thermoforming Plastic Parts Dongguan Yiyongli Industrial Co.,Ltd. , https://www.absthermoforming.com

Benefits of Road Milling

How Does Road Milling Work?

Key Features to Consider When Choosing a Road Milling Machine

SANY India Road Milling Machines

In Summary