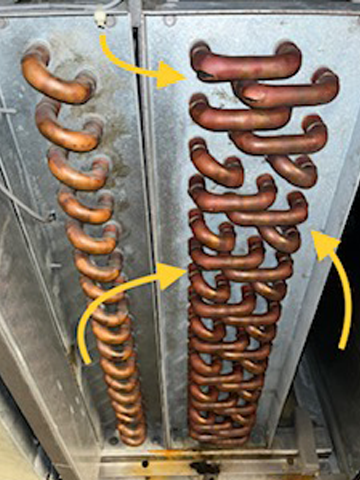

Brace yourself—let’s take a look at a common issue during winter: the frozen water coil. This story takes place at a condominium complex in New York City. As temperatures drop each winter, we field numerous calls about frozen water coils. Recently, we visited a project at a condominium in New York City, where the water inside a Dunham-Bush® unit froze, causing the u-bends to rupture. This specific unit featured a two-row hot water coil and a four-row chilled water coil, both using 5/8-inch copper tubing. Because the unit relied entirely on outside air, it was the first one exposed to the harsh cold when the dampers were open. Ideally, a freeze stat—a temperature sensor designed to shut off dampers when the temperature dips below freezing—would have prevented this from happening. Unfortunately, the freeze stat in this unit was malfunctioning, leaving the dampers open and allowing the water within the copper coils to freeze solid. When water freezes into ice, it expands by approximately 9% in volume, exerting immense pressure on the coil walls and leading to cracks and ruptures. This incident serves as a reminder of why proper maintenance and monitoring of HVAC systems are crucial, especially during colder seasons. To Repair or Replace? That’s the Dilemma. In this case, the decision was made to replace the entire coil. However, often, these ruptured u-bends can be fixed through brazing, a process where metal components are joined by melting and flowing filler material into the joint. The choice between repair and replacement depends on several factors: Have you encountered a similar situation with your water coil—or perhaps another type of coil requiring attention? Don’t hesitate to reach out! At Nationwide Coils, we specialize in manufacturing custom and OEM replacement coils for every unit, regardless of make, model, or year. Whether it’s a frozen coil or any other issue, we’re here to help. Hard Parts For Automobile Maintenance CHANGGE FUKANG MACHINERY ACCESSORIES CO. ,LTD , https://www.fukangcasting.comSite Bite: Burst U-Bends in a Frozen Water Coil

Written by: Jack Kessler

Intern, Nationwide Coils