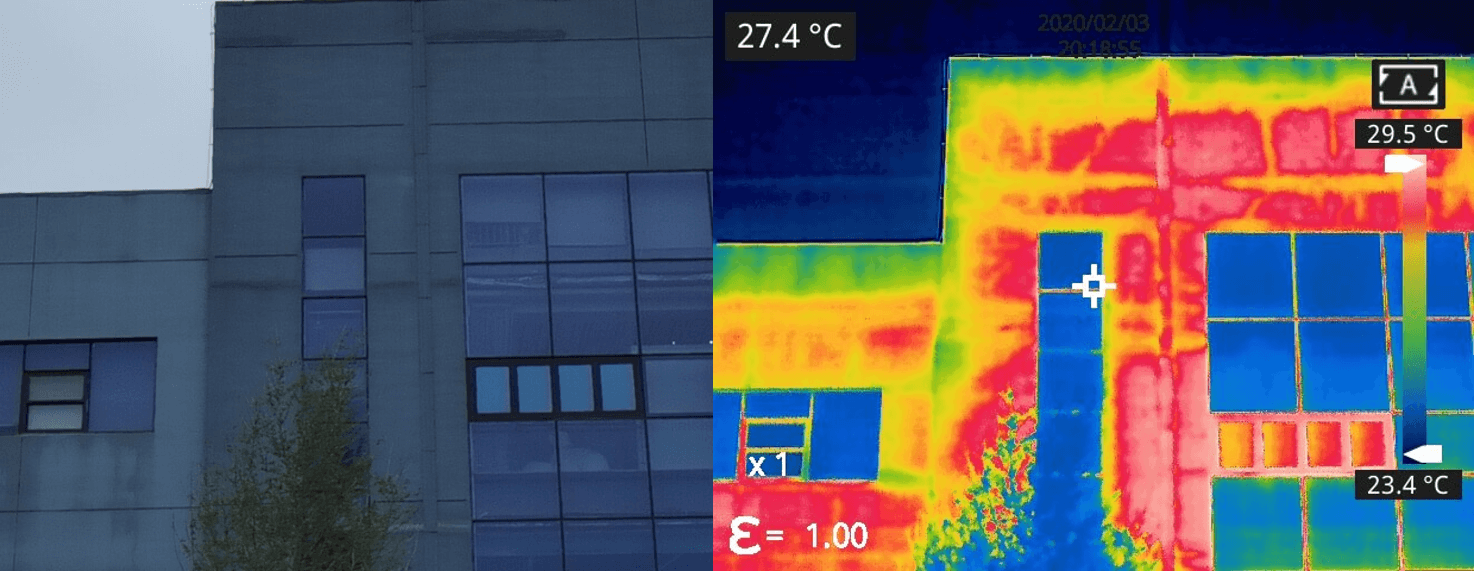

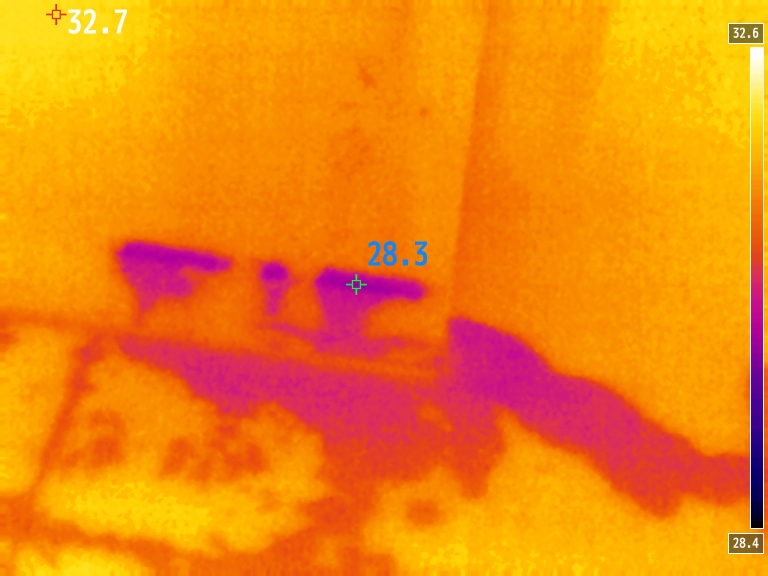

Thermal imaging cameras have revolutionized how professionals approach building diagnostics. These advanced tools allow experts to efficiently assess energy efficiency, structural integrity, and moisture-related issues within buildings. Whether you’re a building inspector, energy auditor, or facility manager, integrating thermal imaging into your workflow can significantly enhance your ability to address challenges such as moisture detection. By capturing infrared radiation, these cameras provide critical insights that aid in maintaining optimal building performance. Thermal imagers work by detecting infrared radiation emitted by objects and converting this data into detailed thermal images. Unlike conventional cameras that rely on visible light, thermal imaging cameras operate using infrared wavelengths, making them invaluable for applications where traditional methods fall short. Originally developed for military and security purposes, thermal imaging has since expanded into numerous industries due to its versatility and precision. This technology allows us to visualize aspects of the environment invisible to the naked eye, offering unparalleled visibility into otherwise hidden issues. In conclusion, incorporating thermal imaging into building diagnostics enhances problem-solving capabilities and extends the lifespan of structures. From energy audits to moisture detection and electrical checks, thermal imaging offers a reliable, efficient means of evaluating building conditions. Its ability to uncover hidden anomalies makes it indispensable across multiple sectors, including construction, facility management, and real estate. To explore tailored solutions for your specific needs, consider reaching out to Tempsens Instruments. Our Thermeye640 model boasts a high-resolution 640x480 format, ideal for capturing intricate details in building diagnostics. Feel free to contact us with your requirements; our experts are ready to assist with comprehensive support. Learn More at: catalog/non-contact-temperature-sensors/thermal-imagers/portable-thermal-imaging-camera.html Forged Turbine Flange,Stainless Steel Flange, Forged Stainless Steel tube sheet Jiangyin Golden Machinery Equipment Co.,Ltd , https://www.goldenforgingmetal.com

Understanding Thermal Imaging

Key Applications of Thermal Imaging in Building Diagnostics

Benefits of Thermal Imaging in Building Diagnostics