2.5 Ton Mini Hydraulic Excavator 2.5 Mini Excavator, this type of model currently has a tail and no tail difference, Mini Excavator 2.5 Ton,2.5 Ton Small Excavator,2.5 Ton Mini Excavator New,2.5 Ton Small Digger New Shandong Davoo Machinery Co., Ltd. , https://www.sddigger.com

The engineering additive track used in the overall model is wear-resistant and stable;

This kind of small excavator has beautiful appearance, full power, imported hydraulic engine, stable performance;

Tailless model, beautiful appearance, adopting imported hydraulic system and imported engine, superior performance;

The front end can be equipped with a side swing function, flexible operation in a small space, large counterweight, and the excavator does not tilt its head when the excavator, and the digging force is increased.

# Drone Tank Inspections Revolutionize Safety, Cost, and Efficiency in Oil Storage

PERTAMINA, Indonesia's leading energy company, collaborated with Halo Robotics to revamp a massive oil storage tank at one of its refineries in Balongan. The Elios 2 drone played a crucial role in the inspection process, delivering results that surpassed expectations.

## Key Benefits at a Glance

### Safety

By leveraging the Elios 2 for internal inspections, the need for human entry via rope access and scaffolding was eliminated. This dramatically enhanced safety for the inspection team.

### Return on Investment

Costly inconsistencies between asset owners and EPC contractors were minimized with the Elios 2. Savings were achieved through reduced downtime and the avoidance of expensive scaffolding.

### Efficiency

The Elios 2 drastically improved the efficiency of the inspection process. Established procedures now enable systematic and repeatable assessments of aging assets, facilitating long-term analysis.

### Data Coverage

An Elios drone allows access to previously unreachable areas, collecting vital data swiftly. Teams can gather more information than ever before without risking human entry into confined spaces.

[Watch the video](https://www.youtube.com/watch?v=YOUR_VIDEO_ID) to see the Elios 2 in action.

---

## Introduction

PERTAMINA is Indonesia's national energy provider. In pursuit of better maintenance practices, they engaged Halo Robotics—a Jakarta-based drone tech firm—to assist with a large-scale maintenance initiative at their Balongan refinery. With a processing capacity of 125 mbsd (Thousand Barrels per Stream Day), this refinery is pivotal to the nation's energy supply.

One particular asset requiring attention was a large crude oil storage tank. Built in 1972, this tank mirrors the design of API 650 tanks globally, making the outcomes and methodologies applicable to any refinery utilizing similar tanks.

*A view of the oil storage tank at Balongan refinery.*

---

## Innovating Oil Storage Tank Inspections

PERTAMINA aimed to conduct a comprehensive inspection of a massive crude oil storage tank at the Balongan refinery. This tank, with a capacity of 37,000 m³, is both substantial and aged, constructed in 1972.

The objectives of this project were:

- Update the tank’s original 1972 blueprints with current as-built schematics.

- Conduct a thorough interior inspection to assess EPC (Engineering, Procurement, and Construction) needs.

- Mitigate risks associated with manned entry into tanks by reducing the reliance on rope access.

- Streamline EPC maintenance processes, including evaluation, planning, and execution.

A critical requirement was ensuring data compatibility across all stages of maintenance—from planning to execution—for engineering, procurement, and construction purposes.

To achieve these goals, PERTAMINA divided the project into two key outputs:

1. **Digital Twin Creation**—Generate updated structural data via a 3D scan of the tank.

2. **Confined Space Inspection**—Perform a systematic Close Visual Inspection (CVI) of the tank interior.

This initiative sought to develop replicable processes that could benefit PERTAMINA’s entire network of refineries nationwide.

*Note: This case study focuses solely on the Confined Space Inspection output. For details on Digital Twin creation, refer to Halo Robotics' white paper.*

*Inspectors hard at work inside the oil storage tank.*

---

## Elios Drone for Enhanced Inspections

PERTAMINA entrusted Halo Robotics to integrate advanced drone technology into their maintenance strategy. For the confined space inspection, Halo Robotics selected Flyability’s Elios drone due to its unique features:

- **Collision-Tolerant Cage**: Ideal for indoor inspections, enabling frequent safe contact with assets.

- **High-Quality Imaging**: Equipped with a 4K RGB camera and thermal IR camera for detailed visual data.

- **Professional Lighting**: 10,000 Lumen LEDs with adjustable lighting systems mimic flashlight techniques used by human inspectors.

- **Stabilization & Distance Lock**: Ensures stable flight in GPS-denied environments and allows precise distance control.

- **User-Friendly Software**: Facilitates efficient data review and report generation.

*The Elios 2 performing its inspection duties inside the oil storage tank.*

---

## Gathering Visual Data

The Elios 2 performed beyond expectations during the confined space inspection. Unlike traditional methods requiring rope access and scaffolding, the drone inspection was faster, cheaper, and safer.

Almuayat Librata, Oil and Gas Transportation Manager at Pertamina EP, remarked:

*"The results we’ve achieved with this drone technology exceeded our initial expectations. It will greatly support preventive maintenance efforts, helping us pinpoint defects, apply appropriate repairs, and boost both speed and accuracy."*

During five intensive days, the Elios 2 completed 20–22 flights daily, generating 760 GB of footage—RGB 4K videos at 9 fps and thermal videos. Post-collection, Flyability’s Inspector software processed the data into a formal inspection report.

Halo Robotics highlighted how Inspector streamlined the review process, allowing them to select Points of Interest (POIs), annotate images, and overlay thermal data onto RGB videos. The entire reporting phase took 14 days, including thorough analysis by an API-certified inspector.

---

## Example POI Reports

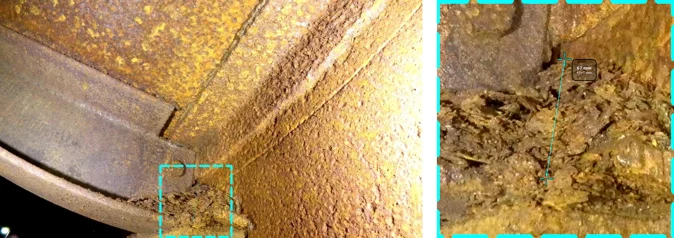

### Corrosion Identified—Tank Joint Left Side

*Inspector Comments:*

- Counted 2 bolts.

- Steel plating and supports show signs of thinning.

- Corrosion spans 0–67 mm from the joint.

- Measurement: 67mm ± 5mm.

### Flaking and Oil Build-Up—Tank Joint Right Side

*Inspector Comments:*

- Counted 2 bolts.

- Significant flaking and oil deposits observed, reaching 67 mm in height.

- Deep, homogeneous corrosion detected.

- Raw metal exposed to oxidation and galvanic reactions.

- Measurement: 67mm ± 5mm.

---

## Looking Ahead

PERTAMINA’s collaboration with Halo Robotics proved highly successful. The confined space inspection demonstrated that drones like the Elios can replace traditional manned entry methods, enhancing safety while reducing costs and improving efficiency.

Erikson Nainggolan, Operation Planning Assistant Manager at Pertamina EP, expressed optimism:

*"We firmly believe that adopting this kind of drone technology will revolutionize tank inspections, lowering risks and expenses while boosting performance."*

With this project completed, PERTAMINA is exploring further applications of drone technology across its Indonesian refinery network.

---

This innovative approach marks a turning point in industrial inspections, paving the way for safer, smarter, and more cost-effective solutions in the energy sector.