Full Hydraulic Road Roller,Mechanical Road Roller,Double Drum Rollers,Asphalt Road Roller Shandong Davoo Machinery Co., Ltd. , https://www.sddigger.com

# Drone Tank Inspections Revolutionize Safety, Cost, and Efficiency in Oil Storage Tank Maintenance

PERTAMINA, Indonesia's national energy company, recently partnered with Halo Robotics to overhaul a massive crude oil storage tank at one of its refineries in Balongan, Indonesia. The Elios 2 drone played a crucial role in this project, delivering impressive results that exceeded expectations.

## Key Benefits in a Nutshell

### Safety

By replacing manual entry through rope access and scaffolding with the Elios 2 drone, the inspection became much safer. This eliminated the risks associated with human presence inside confined spaces.

### Return on Investment

The Elios 2 significantly reduced inconsistencies between asset owners and engineering, procurement, and construction (EPC) contractors. It also saved costs by cutting downtime and eliminating the need for expensive scaffolding.

### Efficiency

The Elios 2 dramatically enhanced the efficiency of the inspection process. By enabling systematic, repeatable inspections, the drone streamlined procedures for analyzing aging assets, providing valuable insights for long-term planning.

### Data Coverage

The Elios drone accessed areas previously unreachable by humans, collecting vital data swiftly. This led to more comprehensive inspections and better-informed decision-making.

## Introduction

PERTAMINA is the national energy provider for Indonesia. Recognizing the need to enhance its maintenance practices, the company engaged Halo Robotics, a local drone technology firm, to assist with a major overhaul at its Balongan refinery. This facility has a processing capacity of 125,000 barrels per stream day.

The specific asset targeted for maintenance was a large crude oil storage tank. Built in 1972, it shares similar characteristics with API 650 tanks used globally for bulk oil and gasoline storage, making the project's findings relevant to any refinery utilizing such tanks.

*A view of the oil storage tank at the Balongan refinery.*

## Innovating Oil Storage Tank Inspections

PERTAMINA aimed to conduct a thorough inspection of this massive crude oil storage tank at its Balongan refinery. With a capacity of 37,000 cubic meters, the tank is both immense and aging.

The objectives of this maintenance project were:

- Update the tank’s original 1972 drawings with accurate as-built schematics and blueprints.

- Perform a systematic internal inspection to identify EPC requirements.

- Minimize inspection personnel risks by reducing reliance on rope access and manned entry.

- Enhance the overall efficiency of EPC maintenance processes, including evaluation, planning, and execution.

Crucially, the data gathered had to be interoperable across all stages of the maintenance lifecycle—engineering, procurement, and construction.

To meet these goals, PERTAMINA divided the project into two outputs:

1. **Create a Digital Twin**: Generate updated as-built schematics and structural data via a 3D scan of the tank.

2. **Confined Space Inspection**: Conduct a comprehensive Close Visual Inspection (CVI) of the tank interior.

The ultimate aim was to establish replicable processes that could be applied across PERTAMINA’s nationwide operations.

*Note*: This case study focuses solely on the Confined Space Inspection output. For details on the Digital Twin creation, refer to Halo Robotics' full white paper.

*Inspectors working inside the oil storage tank.*

## Implementing the Elios for Drone Tank Inspections

Halo Robotics, a leader in drone technology, was tasked with introducing innovative solutions to deliver both outputs. For the confined space inspection, they selected the Elios drone due to its exceptional features:

- **Collision-Tolerant Cage**: Ideal for indoor inspections, allowing safe contact with assets.

- **High-Quality Image Capture**: Equipped with a 4K RGB camera and thermal IR camera for detailed visual data.

- **Professional Lighting**: 10,000 lumen LED lights with direct and oblique lighting options replicate flashlight techniques used by human inspectors.

- **Stabilization and Distance Lock**: Enables stable flight in GPS-denied environments and allows precise distance measurements.

- **User-Friendly Software**: Simplifies data review, reporting, and analysis.

*The Elios 2 in action during the drone tank inspection. The newer Elios 3 now offers LiDAR capabilities.*

## Gathering Visual Data During the Drone Tank Inspection

The Elios 2 surpassed PERTAMINA’s expectations for the confined space inspection. Unlike traditional methods requiring human entry with rope access and scaffolding, the Elios drone offered numerous advantages:

- Enhanced safety

- Reduced operational costs

- Increased inspection efficiency

Almuayat Librata, Oil and Gas Transportation Manager at Pertamina EP, expressed enthusiasm: "The results obtained with this drone technology have far exceeded our expectations. Such operations will greatly support preventive maintenance, helping us pinpoint defects accurately and execute appropriate maintenance faster."

## Drone Tank Inspection Mission Details

Halo Robotics designed flight plans targeting specific areas of the tank, including the shell, welds, rafters, girders, joints, and roof. Over five days, the team conducted 20–22 flights daily, resulting in 760 GB of inspection footage (RGB 4K videos and thermal recordings).

Post-collection, the raw data was processed offsite using Flyability’s Inspector software to generate a formal inspection report. The software facilitated easy review of large volumes of 4K RGB and thermal videos, identification of Points of Interest (POIs), annotations, and comparison of thermal and RGB data.

The entire process, including comprehensive reviews and annotations by an API-certified inspector, took 14 days.

## Point of Interest (POI) Reporting Examples

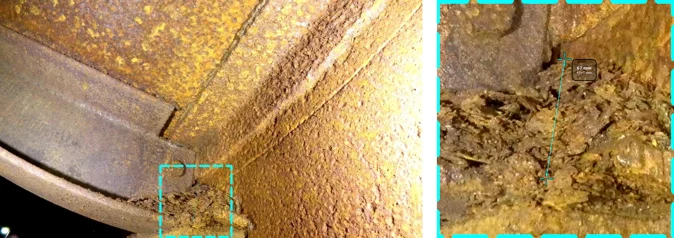

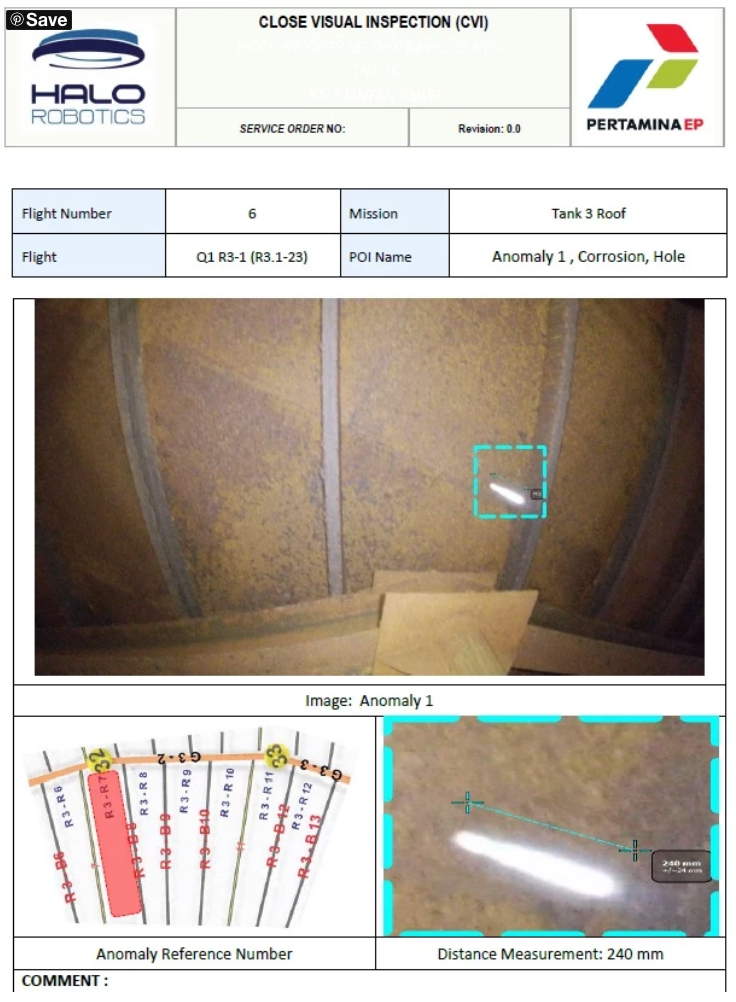

**Corrosion Identified—Tank Joint Left Side**

Inspector Comments:

- Counted 2 bolts

- Detected shrinking steel thickness and supports

- Noted corrosion ranging 0–67 mm from the joint

- Measured distance: 67 mm ± 5 mm

**Flaking and Oil Material Build-Up—Tank Joint Right Side**

Inspector Comments:

- Counted 2 bolts

- Observed significant flaking and oil deposits, buildup height 67 mm

- Identified homogeneous deep corrosion

- Noted deformation exposing raw metal to oxidation and galvanic reactions

- Measured distance: 67 mm ± 5 mm

*Sample report generated by Flyability’s Inspector software.*

## Looking Ahead

PERTAMINA personnel viewed the Elios drone’s performance as a major success. The confined space inspection proved that drones could replace manned entry safely and efficiently, even for large tanks like this one.

Erikson Nainggolan, Operation Planning Assistant Manager at Pertamina EP, remarked, "We firmly believe this technology will revolutionize tank inspections by reducing risks and costs while enhancing safety and efficiency."

With this project completed, PERTAMINA is collaborating with Halo Robotics to explore further applications of drone technology across its Indonesian refinery network.

This initiative marks a pivotal step toward smarter, safer, and more cost-effective maintenance practices in the energy sector.