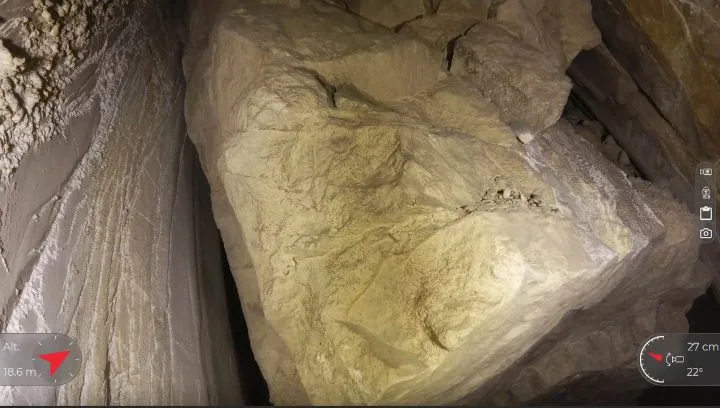

Accessibility The Elios 3 offered unprecedented access to the blocked ore pass. With its advanced LiDAR sensors and live visual feed, it provided both a detailed visual inspection and a 3D model of the blockage, revealing the exact nature and position of the obstruction. Efficiency Instead of the two-month ordeal that traditional methods required, the Elios 3 drastically reduced the time spent on identifying the blockage to mere minutes. Precision The geolocational data from the Elios 3’s 3D mapping enabled teams to pinpoint the exact location of the blockage, negating the need for countless hours of exploratory drilling and guesswork. At a major mining site, workers rely on a complex system of ore passes to transport extracted materials from higher levels to lower ones. These passes act as vertical conduits where the mined ore naturally flows downward to meet haulage vehicles. However, when a blockage occurs, known as a "hang-up," it disrupts the entire flow of materials and requires immediate attention. In this instance, the hang-up occurred in a particularly difficult-to-access part of the ore pass, making it nearly invisible from below. Initial attempts using conventional scanners only revealed a vague outline of the problem area, requiring extensive drilling to confirm its exact location and composition. Drone footage capturing the hang-up during the initial investigation Previous efforts to resolve the hang-up involved inserting cameras and scanners into the ore pass via small access points, but these methods yielded limited results. Teams drilled numerous exploratory holes, each requiring careful placement based on assumptions about the blockage’s location. After weeks of effort, they managed to extract some debris, but the core of the problem remained untouched, leaving the ore pass effectively useless for two full months. A CMS scan showing the general area of the hang-up Despite repeated attempts, the team failed to make substantial progress. Management eventually decided to abandon the area, leaving the hang-up unresolved and the ore pass unused. Later, representatives from Flyability visited the site to demonstrate the Elios 3 drone’s capabilities. When asked whether the drone could inspect the problematic ore pass, they accepted the challenge. Equipped with both live video streaming and a 3D mapping feature, the Elios 3 promised to offer a comprehensive view of the blockage. With the Elios 3, the team gained instant access to a highly detailed 3D model of the ore pass, complete with precise geolocation data. This allowed them to visualize the blockage in ways never before possible. Within minutes, the Elios 3 delivered critical insights about the blockage. Contrary to previous beliefs, the hang-up wasn’t caused by multiple smaller rocks but rather by a single massive boulder. Understanding this distinction was vital for devising an effective clearing strategy. Instead of using multiple small explosives, a single powerful charge could have fragmented the boulder into manageable pieces, restoring functionality to the ore pass. A 3D reconstruction of the blockage generated by the Elios 3’s LiDAR data Here’s how the Elios 3 improved the situation: Following this success, mine operators plan to integrate the Elios 3 into their routine maintenance procedures. By leveraging its capabilities, they hope to address similar issues proactively, reducing downtime and enhancing operational efficiency across the board. Moreover, they envision expanding the drone’s role beyond hang-ups to include routine inspections of hard-to-reach areas within the mine. The potential applications seem endless, promising enhanced safety, precision, and productivity for years to come. Tungsten Carbide Slitting Blade,Slitter Blade,Roll shear knife,Roatry Slitting Knives,Circular knives,Rotary shear blades,Rotary slitter knives HuataoGroup , https://www.industrial-knives.cn3D Mapping with Elios 3 Resolves Ore Pass Blockage in Record Time

In a large-scale mining operation in Colorado, crews faced a significant challenge when an ore pass became blocked, halting ore movement entirely. Traditional methods proved slow and inefficient, taking nearly two months of effort without resolving the issue. However, the introduction of the Elios 3 drone transformed the situation dramatically, allowing crews to locate and understand the blockage in just ten minutes.

Key Benefits at a Glance

Background

Challenges Faced

Solution

Outcomes

Future Implications

The mainly advantage:

Slitting Knives

Huatao supplies high-quality tools for technical applications. Our features include absolute precision, long service life, maximum speed, and reliable quality.

Our product range includes rotary slitter knives, straight knives, and other tools for the metal industry. which is mainly for slitting, trimming, and Shearing systems for the processing industry of steel and non-ferrous materials.

ROTARY SLITTER KNVIES:

Standard tolerances of +/- 0.002 mm

Ultra-precision tolerances of +/- 0.001 mm

STRAIGHT KNIVES / SHEAR BLADES:

Ground version with precision tolerances suitable for every machine.

Individual choice of materials for every application.