Handling bulk materials often requires a variety of size reduction equipment to suit different industrial needs. When acquiring such machinery, it’s essential to consider not just the upfront cost but also long-term factors like energy efficiency and operational expenses. Noise levels and dust production are additional considerations that can impact workplace safety and employee satisfaction. Custom-built equipment typically performs better than off-the-shelf solutions, making it advantageous to collaborate with manufacturers offering diverse size reduction equipment and the ability to tailor their performance to your specific system. Many manufacturers provide material testing services to ensure the equipment meets customer requirements. Such thorough testing minimizes the need for on-site adjustments and ensures you receive the right equipment. Prater Industries stands out for its high-quality size reduction equipment and a customer-centric approach within the bulk material processing sector. Prater’s test laboratory allows clients to identify the ideal type or types of particle selection equipment for their needs. Our engineers are always ready to assist with particle size reduction, separation, and other material handling solutions. Additionally, we offer an interactive tool on our website to help potential customers determine the appropriate machinery for their application. Prater’s equipment selector tool suggests which machines can process material to a specific particle size and provides an animation demonstrating how material moves through each piece of equipment—understanding how our products process material helps companies customize their systems to achieve the desired particle size and separation solutions. Let’s explore Prater’s product line to see what types of size reduction equipment align with your facility’s requirements. Also known as flake breakers or lump crushers, these robust pieces of equipment are integral to most material processing systems. They help break down agglomerated product that has been compressed during blending, transfer, or storage. Using gentle impact and shear forces, these machines improve flowability and enhance product quality, streamlining production. Prater’s Lump Breakers differentiate themselves with single shafts, whereas flake breakers have a lower profile and dual shafts. Both types are used for scrapping and recycling operations and reducing agglomerated material. Features of Prater’s standard Lump Breakers include: Prater’s engineers have also developed a model that is easier and safer to clean and maintain. Similar to our Quick-Take-Apart rotary airlock valves, it allows tool-free access to the drive. The drive unit smoothly slides out on the mounted rail system for convenient access. This upgraded model offers manufacturers increased uptime and decreased dust in production compared to our standard model. Features of Prater’s Quick-Clean Lump Breaker include: Both types of size reduction equipment can process materials such as ash, detergents, fertilizers, paper waste, rubber, and sulfur. Previously known as the Prater Pulverizing Company, the company originally produced the Prater Pulverizer, setting the foundation for modern hammer mills. Prater engineers consistently integrate cutting-edge technology into their hammer mills to enhance material processing capabilities. The Prater G-series represents a full-screen hammer mill designed for high throughput, ensuring energy efficiency and uniform particle size. Committed to maximizing productivity, their screen technology effectively captures material from the grinding chamber, reducing processing energy and operational costs. Features of Prater’s full-screen hammer mill include: Prater’s Mega Hammer Mill processes material to a consistency between our standard Hammer Mills and Fine Grinders. It operates smoothly and quietly, avoiding heat buildup with consistent grinding. The Mega hammer mill is designed for minimal downtime, requiring less airflow than Prater’s standard hammer mills. It is built to run continuously, needing less power and maintenance. Features of Prater’s Mega Mill hammer mill include: Both types of hammer mills can be used to process materials such as barley, clay, gelatin, oats, potatoes, and vermiculite. Prater's Fine Grinders utilize high-speed impacts to break down raw materials introduced into the mill through measured feeding. These machines, often referred to as fine grinding mills, move material across screens and jaws, creating shear and impact forces. Stationary features slow down particles, allowing them to bounce back to the rotor blade's path. Once properly sized, the material is pulled through the screen apertures. Prater's M-series Fine Grinders pulverize materials down to 400 mesh (37 microns) with a more uniform size distribution. The design enables easy rotor access, ensuring close tolerances between the grinding components for finer particles. Despite having a larger screen for its power, the fine grinder can handle substantial throughputs. Features of Prater’s M-series Fine Grinders include: The 10-bar Fine Grinder is built to withstand explosions, with a pressure limit of 145 psi (equivalent to 10 bar). It processes heat-sensitive materials into precise particle sizes and offers bearing monitoring for early failure detection. Features of Prater’s 10-bar Fine Grinders include: While Prater’s 10-bar Fine Grinder specializes in processing environments where dust explosions are a factor, such as sugar grinding (from 4X to 12X), our M-series Fine Grinder can process materials like charcoal, coffee, flour, limestone, resins, and wheat. Known as a classifying impact mill, Prater’s Air Classifying Mills use a dual-stage milling and grinding process that integrates an air classifier into the milling machine. The air classifier recirculates material within the mill while it is running, continuously sending oversized particles back to the grinding zone until they reach the desired size. Prater's air classifying mill provides a rational solution for products that require a narrower range of particle distribution or are simply more challenging to grind. Like other types of size reduction equipment made by Prater, it allows easy cleaning and inspection of the machine’s internal parts, including the classifier and main rotor. Features of Prater’s air classifying mills include: Prater’s air classifying mill can process materials like activated carbon, corn meal, iron oxide, lactose, salt, and zinc oxide. In many material handling systems, rotary airlock valves are essential. These mechanisms work with different types of size reduction equipment, such as airlocks, feeders, or even both airlocks and feeders. Prater’s Rotary Airlock Valves improve material processing systems’ performance, mitigating dust explosions. Our valves provide precise unloading and loading of materials for metering dry materials, though they can also function as efficient rotary airlocks that minimize pressure loss. Prater manufactures various rotary airlock valves, each uniquely designed for specific applications. Prater’s rotary airlock valves include: Rotary airlock valves are crucial in processing applications where dry and free-flowing materials are handled, whether as powders, pellets, granules, or crystals. Prater’s rotary airlock valves are commonly used for cement, fly ash, lime, ores, pharmaceuticals, and sugar. We manufacture various other kinds of machinery in addition to the various types of size reduction equipment Prater makes. Other equipment made by Prater includes: To learn more about our product lines and services to support our customers, contact the material handling experts at Prater today.   Cnc Horizontal Lathe,Cnc Horizontal Lathe Machine,Cnc Lathe Machine,Industrial Lathe Machine Suzhou Loong Won Machinery Technology Co., Ltd. , https://www.loongwon.comDifferent Types of Size Reduction Equipment from Prater

Lump Breakers

Lump Breakers

Hammer Mills

Hammer Mills

Fine Grinders

Fine Grinders

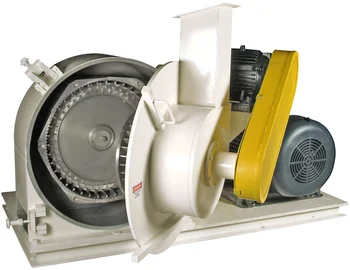

Air Classifying Mills

Air Classifying Mills

Rotary Airlock Valves

Rotary Airlock Valves

Other Prater Equipment

Cnc Horizontal Lathe,Cnc Horizontal Lathe Machine,Cnc Lathe Machine,Industrial Lathe Machine Suzhou Loong Won Machinery Technology Co., Ltd. , https://www.loongwon.com

Posted on September 5, 2024, 1:57 PM